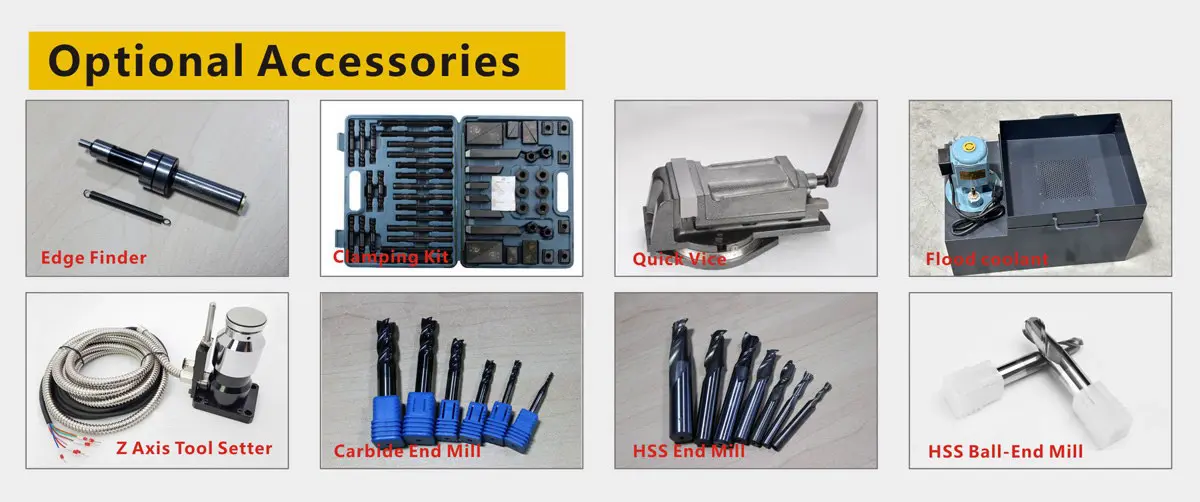

The VMC200 is a 3 axis small CNC machine center,available either floor standing or for bench mounting, with high performance 3 axis milling CNC controller,support multi language interface display,the standard spec includes MPG hand wheel.Selection of high -quality casting materials,High-precision linear guide and ballscrews,semi-automatic lubrication system,protect the rail life.5 tools automatic tool change system(ATC),ISO20 spindle type, frequency conversion water cooling spindle motor, low noise, 24000rpm spindle supreme speed.Standard spec XYZ axis is stepper motor ,option AC servo motor.with the option of flood coolant with industrial cabinet base and and automatic aligning instrument.Ideal for cutting a range of resistant materials such as wax, plastic, acrylic, free cutting alloys,aluminium and steel. Recommended software programs( MasterCAM、UG、Fusion360, SolidWorks).Suitable for technology development, advertising design, art, ocational technical college Education & Training CNC and DIY enthusiasts.

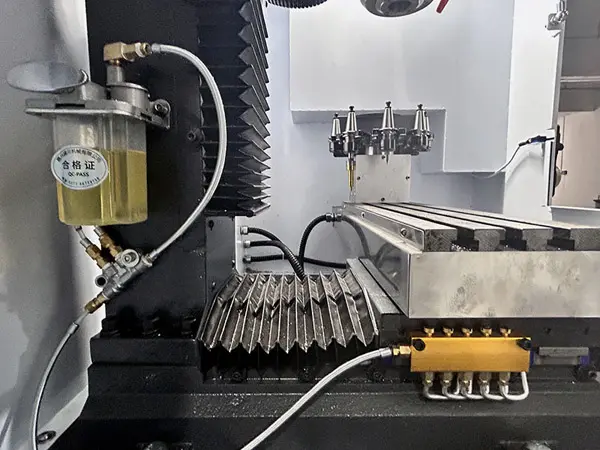

Machine tool bod selection of high-quality casting materials,high-precision linear guide and ballscrews,semi-automatic lubrication system,protect the rail life,Experience the pinnacle of precision, reliability, and longevity with our Small CNC Machine, featuring a high- quality casting materials for unwavering rigidity, high-precision linear guides and ball screws for unmatched precision, and a multi-line semi-automatic lubrication system for extended machine lifespan.

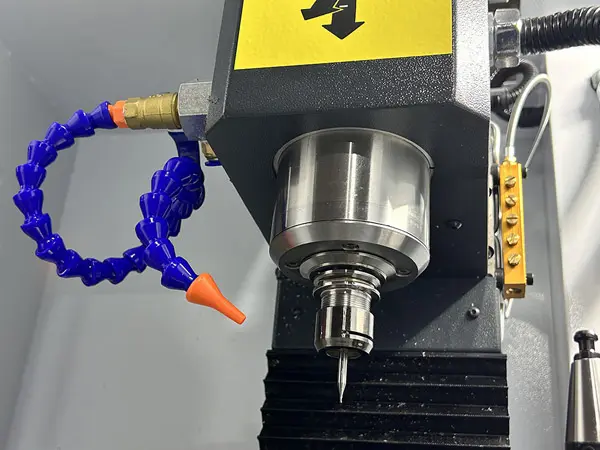

Our high-performance spindle delivers exceptional power and versatility, catering to a wide range of machining needs. The variable-frequency drive allows for precise speed control, optimizing performance for specific materials and applications. With manual and automatic tool change capabilities, our control system adapts to your workflow, empowering you to achieve operational excellence.

The robust 5-station self-locking rotary tool carousel safeguards against misoperation, while the protective dust cover ensures that machining accuracy remains uncompromised. Experience the pinnacle of precision with our water-cooled spindle, variable-frequency drive, and pneumatic tool change, ensuring consistent performance and unwavering accuracy.

The 4-axis 3-level adjustable pulse electronic handwheel provides unparalleled precision control, allowing you to make fine adjustments with ease. Experience the pinnacle of control and achieve unmatched accuracy with our intuitive and user-friendly control system.

Our 8.4-inch color LCD screen provides a clear and intuitive interface, while the integrated handwheel trial cutting function allows you to verify the accuracy of your program and positioning before committing to the final machining process. With support for future feature upgrades, our control system ensures you stay ahead of the curve.

Our large-capacity circulation cooling water tank, equipped with a filtration system, effectively dissipates heat and removes impurities, ensuring optimal performance and extending the lifespan of your tools and spindle. With manual and automatic control options, our system adapts to your specific needs.

Technical parameters |

|

X axis travel |

230mm |

Y axis travel |

130mm |

Z axis travel |

220mm |

Spindle taper |

ISO20 |

Automatic tool change system(ATC) |

5 Tools |

Pneumatic supply |

0.6 MPa |

Tool DIA. range |

1-13mm |

Control system |

|

Spindle Power |

1.5kw |

Spindle speed |

100-24000rpm |

Motor Type |

Step motor(Option AC servor motor) |

| The max moving speed | 2000mm/min |

| The max feeding speed | 1000mm/min |

| Positioning accuracy | 0.02mm |

| Repeatability accuracy | 0.01mm |

| Transmission | ball screw |

| guide rail | High-precision linear guide |

Table size |

460*130mm |

Number of T-slots |

3 |

Width of T-slot |

12mm |

Table structure |

Full cast iron |

Power |

230VAC / 110VAC |

Weight(NW/GW) |

180/230kg |

Overall dimension |

900×680×1000mm |

Packing size |

960×750×1200mm |