(1).VMC300 small 5 axis CNC machine center standard configuration use 220/110VAC single phase voltage,choose Siemens system or Fanuc system with 380VAC voltage.With interlocking protective devices, use high-accuracy linear guides and ball screws, machine tool body cast with high-quality cast iron materials; Materials that can be processed: steel, iron, copper, aluminum alloy, etc.

(2).Standard configured with YORNEW five-axis linked CNC system, supporting RTCP (rotation tool center point) function, can process small five-axis parts and various complex three-axis parts. Optional other system,such as Fanuc series OI-MF plus controller,SINUMERIK 808D or 828D.

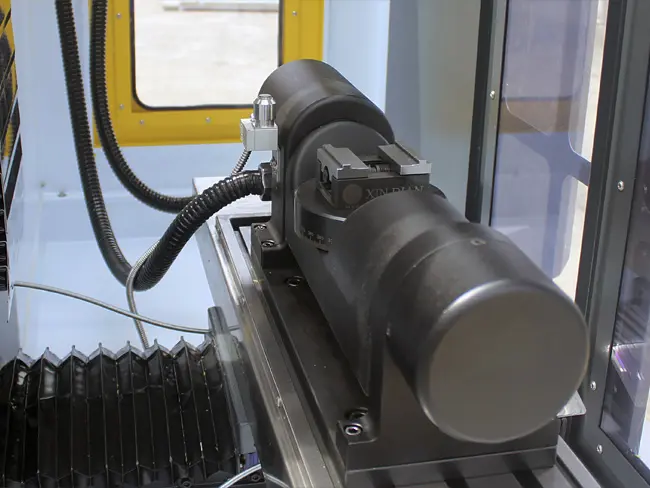

(3).With high-speed spindle that operates at 100-24000rpm, spindle motor power of 2.2 kw,spindle taper is ISO20. The XYZAC axis motors use servo motors ,with a workpiece cooling system liquid circulation system and an automatic tool presette;

(4).Configure automatic tool change system (10 tools), using air pressure of 0.6 Mpa, supporting standard G code and CAM software (MasterCAM, UG, Fusion360, etc.);

Industrial-grade five-axis linked CNC system,supporting RTCP(rotation tool center point) function;8.4-inch color LCD screen,support multi language interface display,ARM 9 CPU FPGA,support B macro function,PLC function.

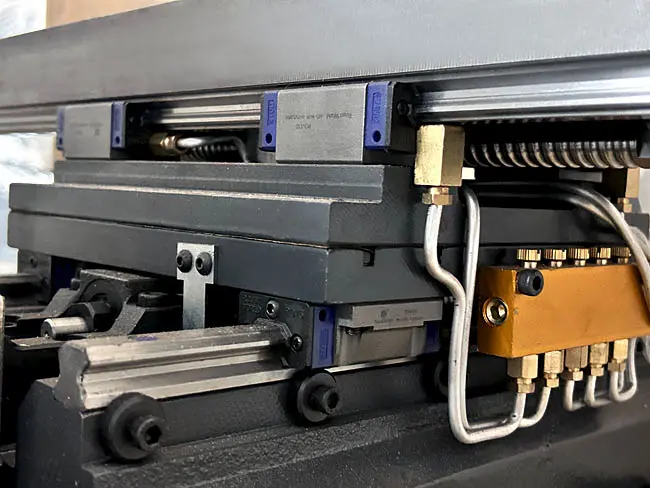

5th axis device use a harmonic gear reducer, it has high precision, zero backlash, and strong self-locking capability. The AC axis uses a 200W servo motor,with aviation plug, plug-and-play,making it flexible and convenient. Remarks:5th axis isn't necessary,you can only buy XYZ axis machine.

Selection high-precision linear guide and ballscrews,machine tool body by casting materials,automatic lubricSation system,protect the rail life,experience the pinnacle of precision, reliability.

Equipped with an ISO20 variable frequency water-cooled high-speed spindle, with a maximum speed of 24000rpm/min and spindle power of 2.2 kW, it features a 10-position automatic tool change system(ATC) ; equipped with an Z axis tool setter to improve tool setting accuracy, reduce machining errors, and save tool setting time.

option online messtaster probe module,it can achieve automatic centering, automatic alignment, angle correction, automatic compensation for square/circular workpieces, and automatic depth compensation for concave and convex platforms.

Our large-capacity circulation cooling water tank, equipped with a filtration system, effectively dissipates heat and removes impurities, ensuring optimal performance and extending the lifespan of your tools and spindle. With manual and automatic control options, our system adapts to your specific needs.

Technical parameters |

||

Positioning accuracy |

0.02mm |

|

Repeatability accuracy |

0.01mm |

|

X axis travel |

310mm |

|

Y axis travel |

180mm |

|

Z axis travel |

290mm |

|

Options 5th axis |

Backlash |

Zero Backlash |

Max Speed 4th axis |

30/R.P.M |

|

Max Speed 5th axis |

30/R.P.M |

|

Accuracy 4th axis |

±1 arc-min |

|

Accuracy 5th axis |

±1 arc-min |

|

Repeatability 4th axis |

20 arc-sec |

|

Repeatability 5th axis |

20 arc-sec |

|

Homing |

A axis |

|

Limits |

+C, -C |

|

4th axis Travel |

A axis:+30° to -120°, |

|

5th axis Travel |

C axis:±infinity |

|

C axis Output Flange Diameter |

120mm |

|

Spindle taper |

ISO 20 |

|

Automatic tool change system(ATC) |

10 Tools |

|

Pneumatic supply |

0.6 MPa |

|

Tool DIA.range |

1-13mm |

|

Standard Size Collet |

1-13mm |

|

Control system |

5 axis CNC center machine controller |

|

MPG hand wheel |

5 axis |

|

Spindle Power |

1.5kw |

|

Spindle speed |

100-24000rpm |

|

Motor Type |

XYZAC axis AC Servo |

|

Rapid movement in X /Y/Z Axis |

1-8000mm/min |

|

Feed rate in X/Y/Z Axis |

1-4000mm/min |

|

Power of X/Y/Z Axis |

AC Servo 750W |

|

Power of A/C Axis |

AC Servo 200W |

|

Transmission |

ball screw |

|

guide rail |

High-precision linear guide |

|

Table size |

550*180mm |

|

Number of T-slots |

3 |

|

Width of T-slot |

12mm |

|

Table structure |

Full cast iron |

|

Power |

230VAC/110VAC |

|

Weight(NW/GW) |

650/700kg |

|

Overall dimension |

1360*990*1800mm |

|

Packing size |

1400*1050*2000mm |

|

VMC300 Small CNC Machine machining Video

VMC300 Small CNC Machine machining Video

VMC300 Small CNC Machine machining Video

VMC300 Small CNC Machine machining Video

VMC300 Small CNC Machine machining Video

VMC300 Small CNC Machine machining Video